Welcome back to the Elemental Hardwoods blog, the most in-depth hardwood species series on the web. Today’s blog is ‘Acclimation – A Critical Component for Successful Solid Wood Flooring Installation’.

Proper acclimation is a critical component in every solid wood flooring install. It is effectively the final stage of the “drying” process that allows a given wood flooring product to equalize and stabilize its internal moisture content to the specific living environment in which it will be installed.

All wood flooring is kiln dried prior to molding it to flooring. It is not all dried equally or to the same moisture content, but rather to within a specific range; i.e. 6-10% or 8-12%. Proper install guidelines require that the moisture content of both flooring and subfloor be tested prior to install and that the acclimation process should be as long as is required for the flooring and subfloor to be stabilized to within 4% of each other if the flooring is 3” wide or less and 2% of each other if the flooring is wider than 3”. There is no way to calculate an exact time-frame for acclimation as it may take less or more time for this equalization to be realized depending on the specific conditions of a given home, subfloor and flooring product. The acclimation process is designed to make certain that a particular product has its moisture content stabilized/acclimated to the appropriate ambient moisture conditions for a particular home/location.

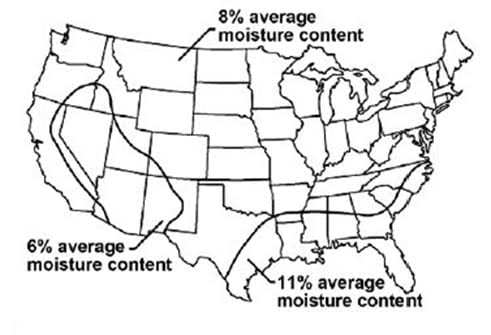

Recommended average moisture content for interior use of wood products in various areas of the United States.

Ambient moisture varies significantly from place to place, home to home, so there is no perfectly dried wood flooring product that applies to all conditions – hence the critical importance of acclimation to allow for the final job-site moisture adjustment/equalization.

It is certain that the vast majority of problems in wood flooring are moisture related and result from too high or too low moisture content in combination with insufficient acclimation prior to install. Depending on a given location and/or application, drying and moisture content may be an important part of any product/sales discussion. Wider boards vs narrower boards and engineered product vs solid wood are adjuncts of this discussion as wider boards will always have more movement potential than narrower boards and solid wood has more movement potential than engineered wood flooring.

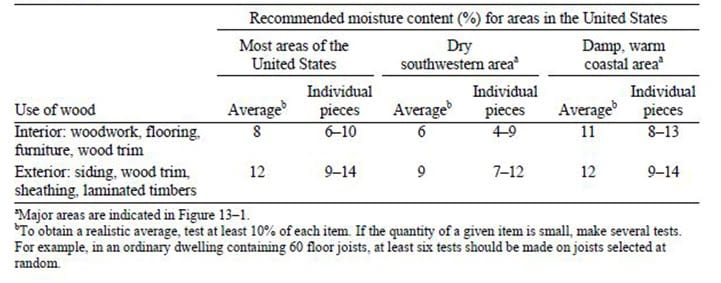

Recommended moisture content values for various wood products at time of installation.

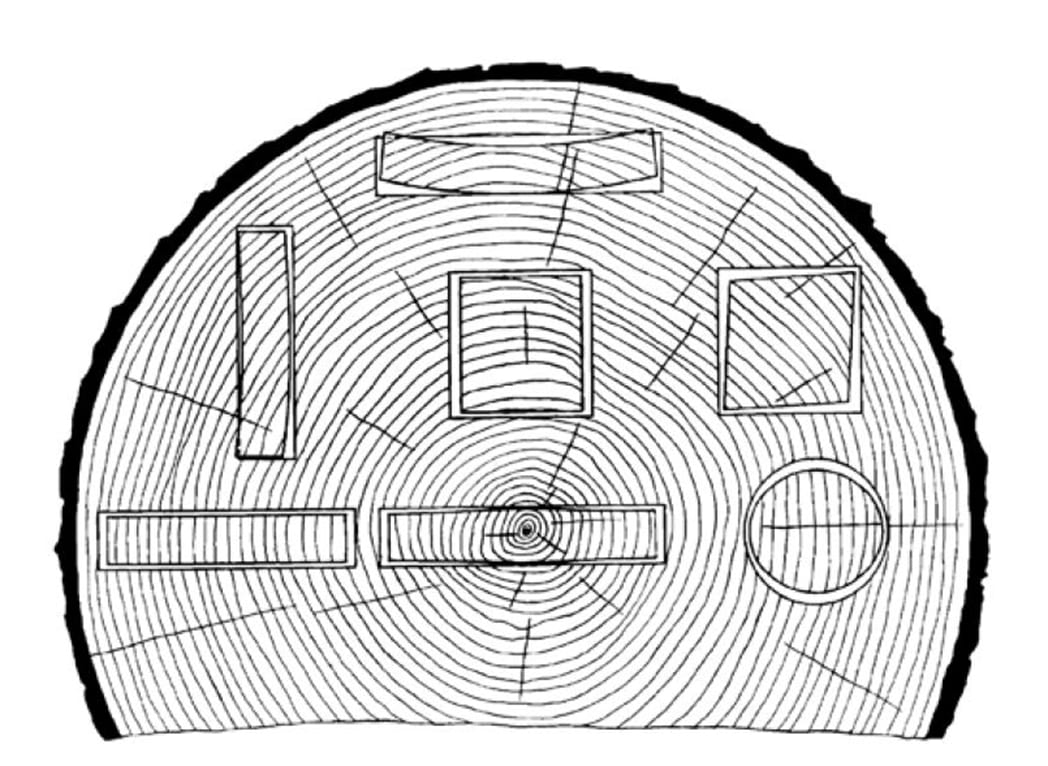

Movement here refers to expansion and/or contraction of solid wood as it takes on or gives off moisture due to higher or lower ambient moisture in a given environment. Moreover, some woods are naturally more stable than other, having higher or lower shrinkage factors depending on the specific individual wood characteristics. The manner in which a solid wood board is sawn from the log also impacts stability/movement as quarter-sawn boards expand and contract less than flat-sawn boards.

Characteristic shrinkage and distortion of flat, square,and round pieces as affected by direction of growth rings.

Tangential shrinkage is about twice as great as radial.

The basic drying and stability concepts are important for anyone working with solid wood flooring to understand. At Elemental we want our customers to be fully informed in order to prevent unnecessary problems that can be easily avoided with a proper understanding of acclimation and installation guidelines when putting in a new wood floor. Accurately checking the moisture content of flooring and subfloor, and ensuring sufficient acclimation time, are the best way to ensure a long-lasting positive result from any new solid wood floor install.

If you have any questions regarding this blog or any of our products, please don’t hesitate to contact us.